A Few Tips When Designing Grundfos Pressure Boosting

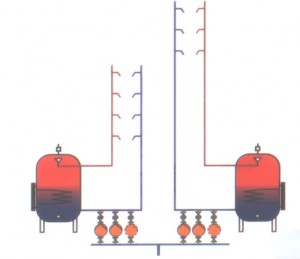

1. Include hot water supply in each zone – Grundfos Pressure Boosting

If the pressure boosting system is divided into zones, we always recommend that you include a hot-water production unit in each zone. Thay way, you avoid large differences in pressure betwen the hot and cold water.

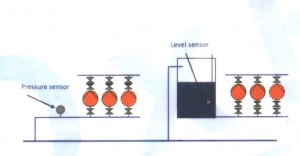

2. Always use dry-running protection ! – Grundfos Pressure Boosting

We always recommend that you add dry-running protection to your pressure boosting system. Exactly how you do this depends on the type of system. If your booster system is connected directly to the water supply, you should use a pressure sensor to monitor that there is sufficient pressure to the pump. If your system uses a break tank, use a level sensor in the tank instead.

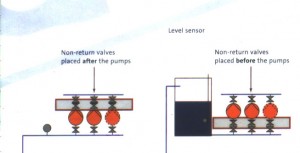

3. Where should I place non-return valves ? - Grundfos Pressure Boosting

In systems exposed to inlet pressure-i.e. systems that are connected directly to the water supply – we recommend that you place the non-return valves after the pumps. This prevent the pressure inside the pump from becoming too low, so you avoid problems with air being sucked through the shaft seal.

If your system is subjected to suction pressure – i.e. if it is connected to a break tank – you should place the non-return valves before the pumps.

Courtesy of PT.Grundfos Pompa

PT. Andalan Inti Rekatama – GRUNDFOS Authorized Dealer – Service Partner –Grundfos Booster Compact

Its such as you read my thoughts! You seem to know a lot about this, like you wrote the e-book in it or something.

i would like to use your pumps for our pressuried water system in our 18 bungalows. Request pl advise us nos of pumps to be used and volume of pressure booster. Design calculation may also be submitted

Regards

R S PATEL